Understanding the Safety and Value of Fiberglass Grating

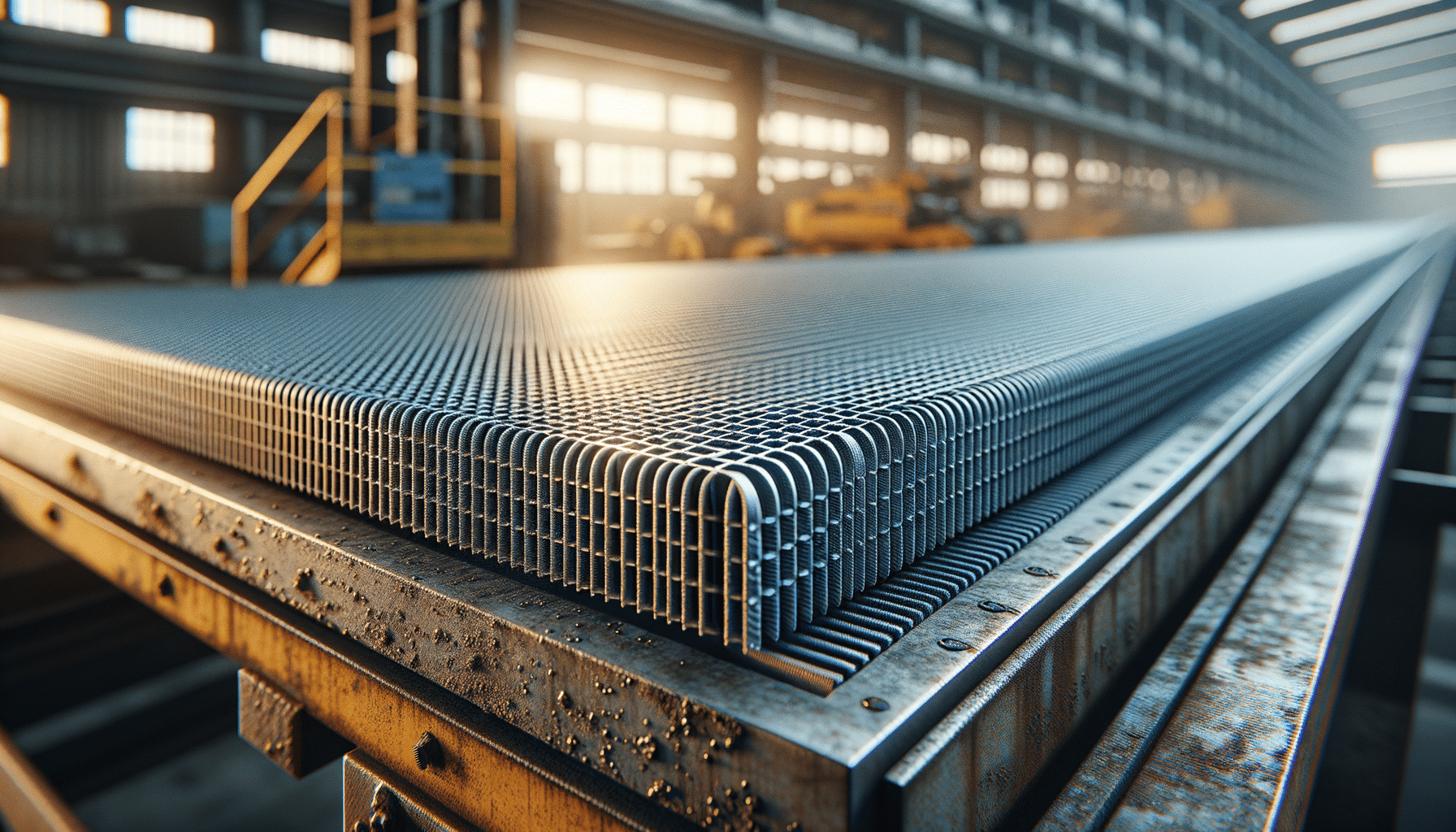

Introduction to Fiberglass Grating

Fiberglass grating is a versatile and durable material widely used in various industries for its unique properties. It is crafted from fine strands of glass woven together and bonded with a resin, resulting in a lightweight yet robust structure. This material is renowned for its corrosion resistance, making it an excellent choice for environments prone to moisture, chemicals, and other corrosive elements.

The value of fiberglass grating lies not only in its durability but also in its safety features. Its non-conductive nature makes it a preferred option in electrical and chemical industries, reducing the risk of electrical hazards. Moreover, the grating’s anti-slip surface enhances safety, providing a secure footing even in wet or oily conditions.

The applications of fiberglass grating are diverse, ranging from industrial flooring and walkways to platforms and stair treads. Its adaptability and resilience make it a cost-effective solution for businesses seeking long-term infrastructure investments.

Safety Features of Fiberglass Grating

One of the primary reasons for the popularity of fiberglass grating is its exceptional safety features. The material’s inherent non-conductivity is crucial in environments where electrical safety is a concern. Unlike metal grating, fiberglass does not conduct electricity, significantly reducing the risk of electrical shocks.

Additionally, fiberglass grating offers an anti-slip surface, which is vital in maintaining safety in workplaces. This feature is particularly beneficial in industries where spills or moisture are common, as it minimizes the risk of slipping accidents. The grating’s surface can be customized with various textures to enhance grip, catering to specific safety needs.

Fiberglass grating is also fire retardant, adding another layer of safety. It is designed to withstand high temperatures without compromising structural integrity, which is crucial in industries exposed to heat or open flames. This fire-resistant property ensures that the grating can help contain fires, providing time for evacuation or intervention.

- Non-conductive, reducing electrical hazards

- Anti-slip surface for enhanced safety

- Fire retardant, maintaining integrity under high temperatures

The Value Proposition of Fiberglass Grating

While the safety features of fiberglass grating are significant, its value proposition extends beyond safety. Its durability and low maintenance requirements make it a cost-effective choice for long-term use. Unlike metal grating, fiberglass does not corrode, rust, or rot, even in harsh environments. This longevity translates to lower replacement and maintenance costs, making it a financially sound investment.

The lightweight nature of fiberglass grating also contributes to its value. It is easier to handle and install compared to traditional materials, reducing labor costs and installation time. This ease of installation is particularly beneficial in large-scale projects, where efficiency and cost savings are crucial.

Moreover, fiberglass grating is available in various colors and designs, allowing businesses to maintain aesthetic appeal without sacrificing functionality. This versatility makes it suitable for both industrial and commercial applications, where appearance and performance are equally important.

- Durability and resistance to corrosion

- Low maintenance and replacement costs

- Lightweight and easy to install

- Available in various colors and designs

Comparing Fiberglass Grating with Traditional Materials

When comparing fiberglass grating to traditional materials like steel or aluminum, several advantages become apparent. One of the key distinctions is the corrosion resistance of fiberglass. Unlike metals, which can rust and degrade when exposed to moisture and chemicals, fiberglass remains unaffected, making it ideal for outdoor and marine environments.

In terms of weight, fiberglass grating is significantly lighter than metal alternatives. This not only simplifies installation but also reduces the load on supporting structures, which can be crucial in certain applications. The reduced weight does not compromise strength, as fiberglass grating can support substantial loads, making it a reliable option for industrial use.

Fiberglass grating also offers better thermal and electrical insulation properties than metals. This makes it a safer choice in environments where electrical conductivity and temperature extremes are concerns. The non-magnetic nature of fiberglass further enhances its suitability for applications where magnetic interference must be minimized.

- Corrosion resistance compared to metals

- Lighter weight for easier installation

- Superior thermal and electrical insulation

- Non-magnetic properties

Conclusion: The Strategic Choice for Industry

Fiberglass grating stands out as a strategic choice for industries seeking a balance of safety, value, and performance. Its unique combination of properties makes it suitable for a wide range of applications, from industrial to commercial settings. The material’s safety features, including non-conductivity and anti-slip surfaces, ensure a secure working environment, while its durability and low maintenance requirements offer cost savings over time.

As industries continue to prioritize safety and efficiency, fiberglass grating provides a forward-thinking solution that meets these demands. Its versatility, coupled with its aesthetic and functional benefits, makes it a preferred choice for modern infrastructure projects. By investing in fiberglass grating, businesses can enhance safety, reduce costs, and ensure long-lasting performance.